AREAS OF EXPERTISE

- Aircraft, Helicopter, Satellite, and Missile Assembly.

- SCIF (Sensitive Compartmented Information Facility).

- Painting, Stripping, Cleaning, and Plating.

- EMI/RFI Shielding and TEMPEST.

- Chemical Milling.

- Machining, Forging, and Casting.

- Additive and Lean Manufacturing.

- Electronic Assembly and Testing.

- Logistics Engineering.

- Defense and Aerospace Manufacturing.

AEROSPACE AND DEFENSE OPERATIONS

- Logistics Engineering

- Lean Manufacturing.

- Aircraft Painting and Stripping.

- Clean Rooms.

- Environmental Control Upgrades.

- Machining, Forging, and Casting.

- Chemical Milling.

- Cleaning and Plating.

- Composites Fabrication.

- EMI/RFI Shielding and TEMPEST.

- Microchip Fabrication.

- Avionics and Electronic Assembly and Testing.

- Logistics and Distribution.

SPECIALIZED FACILITY PROJECTS

- Manufacturing Facilities.

- R&D Laboratories.

- Components Manufacturing Plants.

- Engine Manufacturing and Testing Facilities.

- Training and Simulation Centers.

- Space, Production, and Quality Control Laboratories.

- Paint Hangars.

- Warehouses and Distribution Centers.

- Battle Management and Combat Simulation Theaters.

- Aerospace Plant Construction.

- Defense Manufacturing Plant Design.

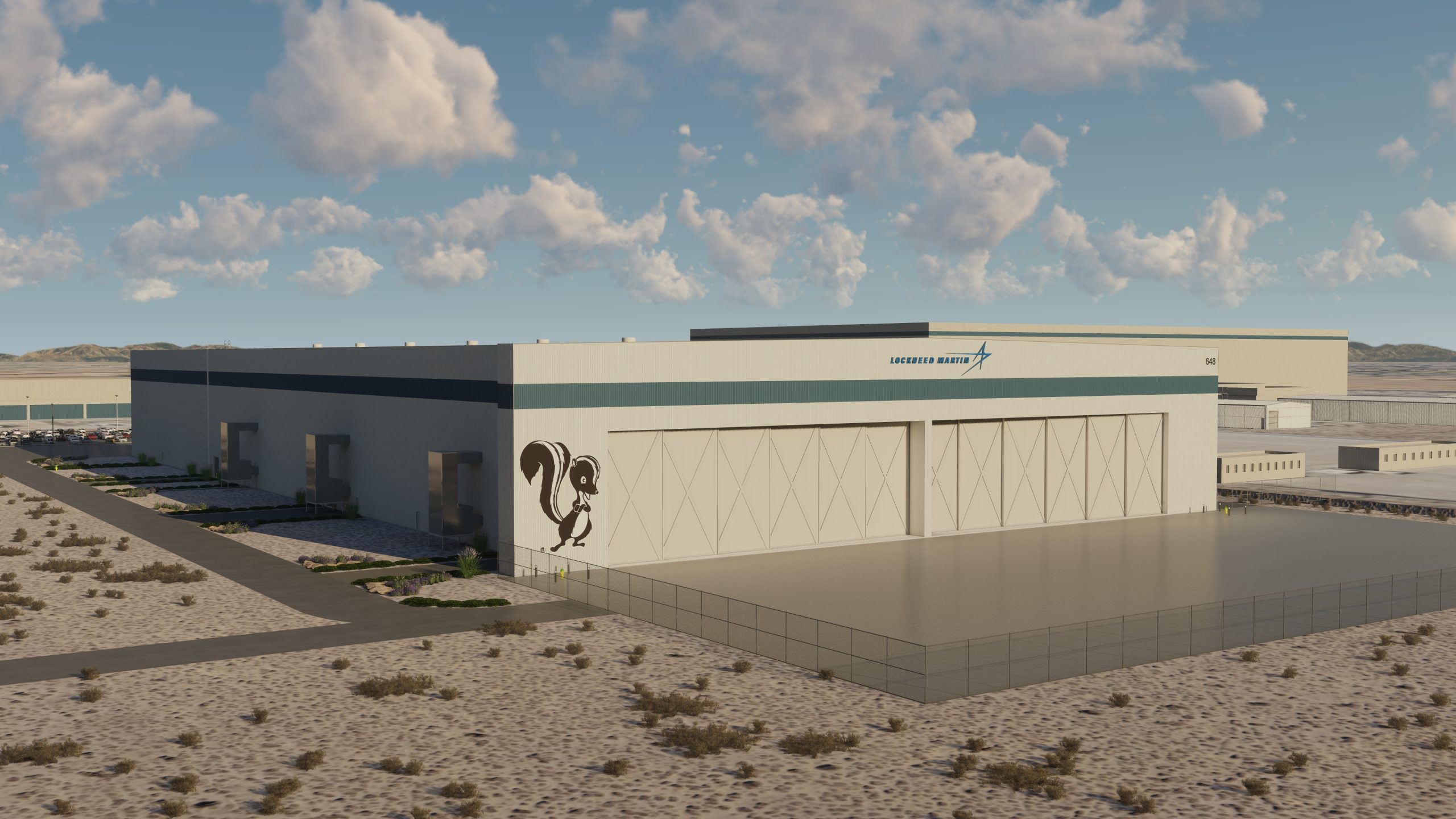

LOCKHEED MARTIN UNVEILS FLEXIBLE FACTORY AT SKUNK WORKS IN PALMDALE CALIFORNIA

The Austin Company served as design-builder on Lockheed Martin’s newest digital factory in Palmdale, California. The 215,000 SF intelligent, flexible factory has digital foundations to incorporate smart manufacturing components, and deliver cutting edge solutions rapidly and affordably to support the United States and its allies.

TO LEARN MORE ABOUT OUR AEROSPACE AND DEFENSE PROJECTS, VIEW OUR PROJECT GALLERY